where have we been?

As we were preparing to launch a new product towards the beginning of 2022, we were immediately faced with challenges: supply chain disruptions for components, chip shortages, and aluminum pricing. At our tiny scale, these challenges made it impossible for us to introduce and make products at a price point that we felt comfortable with.

May/June Update: Array Peripherals Featured

In the past couple months, we’ve been pretty fortunate to have had the opportunity to collaborate with some awesome individuals to provide product giveaways.

April Update: Shipping Orders (+ more countries!) | Experimenting

So… it’s been awhile since we just wanted to give you a quick update with what we’ve been up to - mostly fulfilling orders, adding countries, and planning out what’s next!

Delayed Orders Expected Ship Date - March 3rd

We apologize for the small number that are currently delayed. Thank you for your patience and understanding. We are aiming to resolve the delays and expect to ship all outstanding orders by March 3rd.

Working hard to fulfill pre-orders!

Our current plan is to ship parts out by February 4. We really appreciate your patience as we deal with minor delays related to supply chain, shipping delays, vendor shipments, etc. We apologize that it’s taking a bit longer ….

Design for manufacturing (macro)

There’s a common saying in project management, engineering, manufacturing: “time, cost, quality - choose 2”.

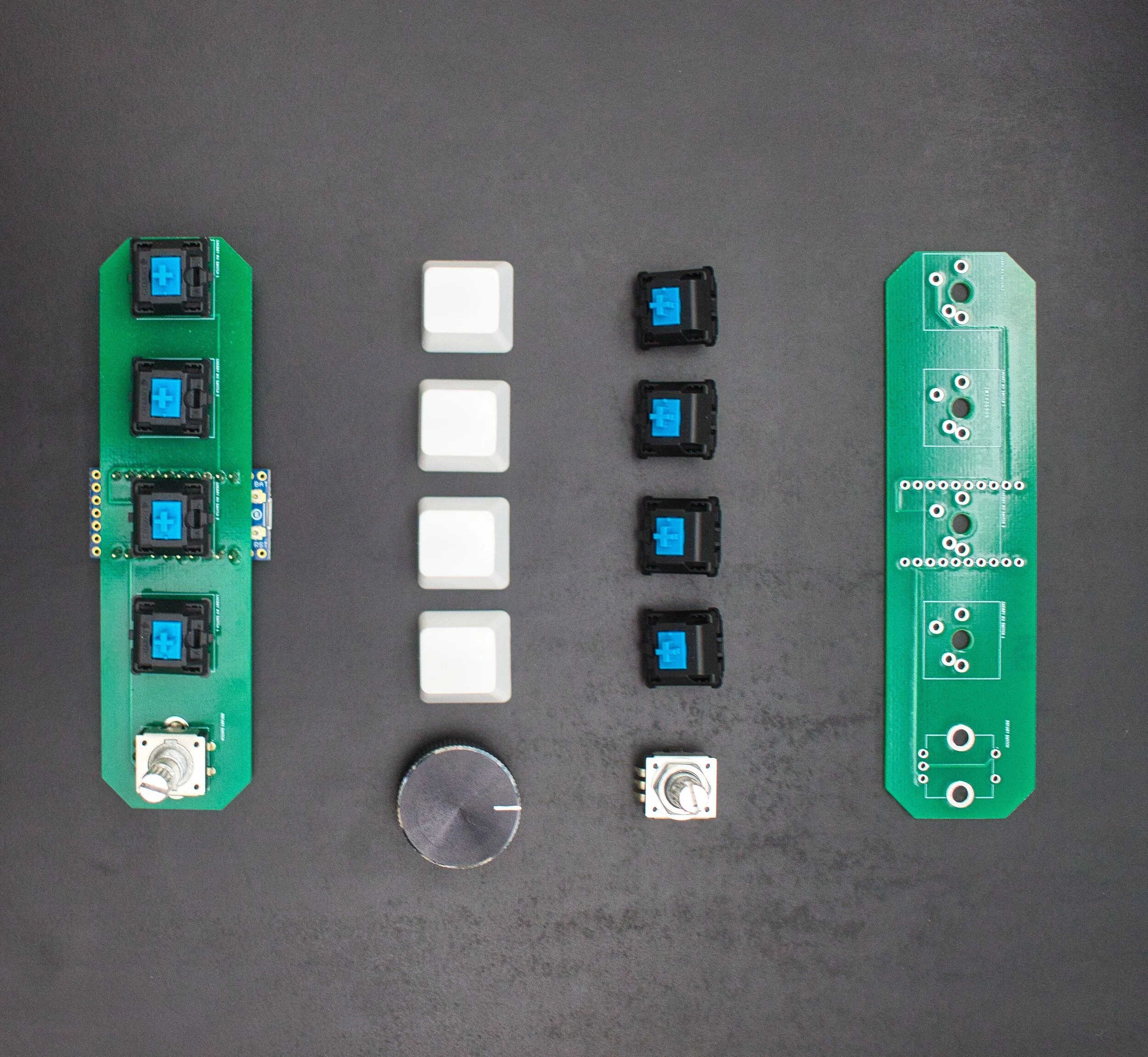

Prototyping Electronics

Keyboards, in general, contain only a small number of major discrete electronic components: the microcontroller unit (MCU) and the key switches.

Post 4: The backend (firmware!)

We take for granted that everything kind of just works without any second thought about how it works. You plug in your keyboard, your computer recognizes it (insert USB chime here), and then it works.

Post 3: Getting it made

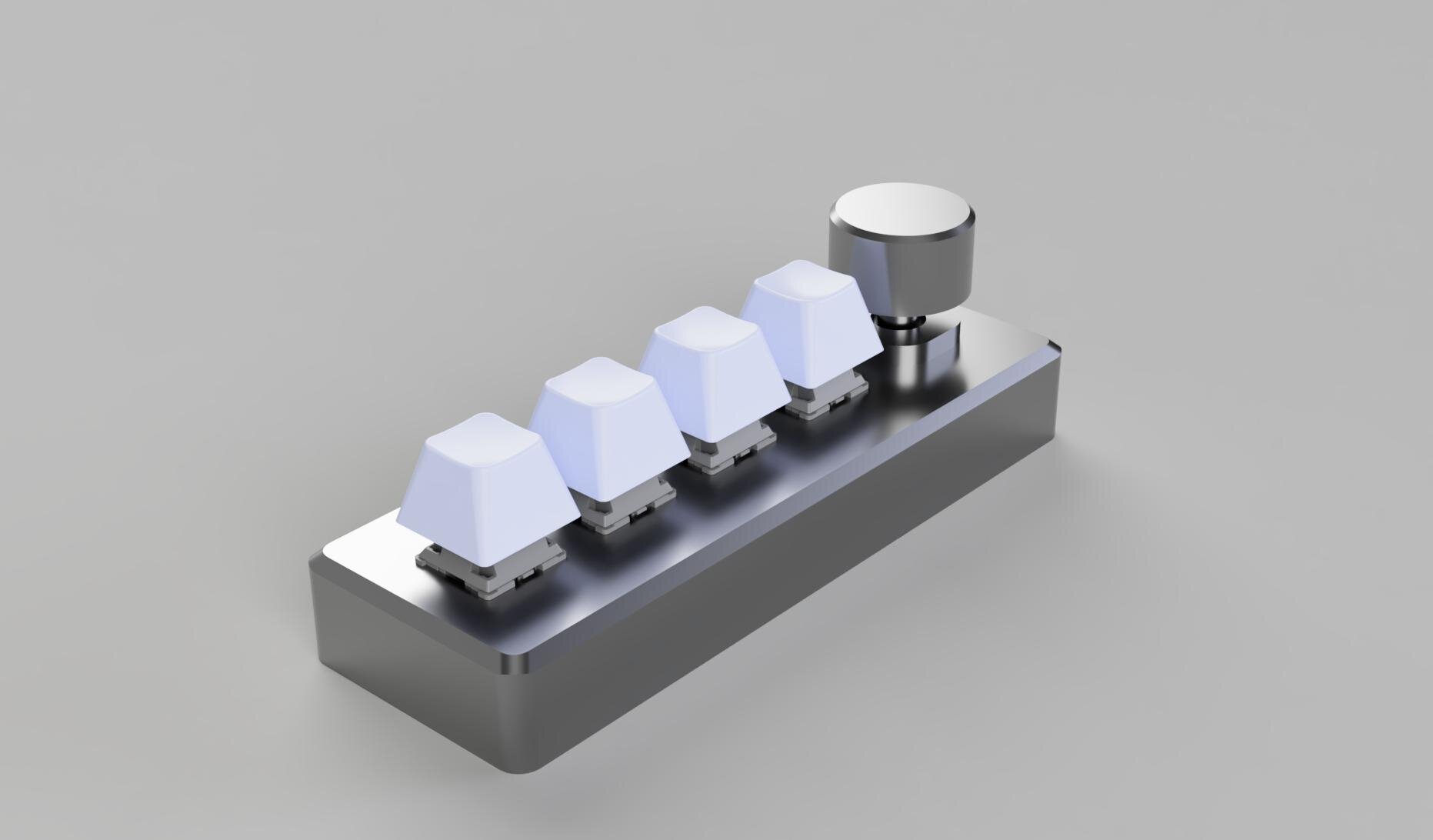

Even before sending parts out for quote, it was very clear that 1) we wanted the enclosure to be a solid aluminum housing and 2) it would be the most expensive single part of the whole thing. A lot of work was done to optimize the design to minimize machining operations and machining time. One of the difficulties that we ran into was the geometry required to mount the mechanical switches.

Post 2: To the drawing board

From this time period, my notepad is filled with sketches of various shapes, form factors, and sizes that the macropad could take. We eventually settled on a few basics constraints that would guide the design:

Post 1: Life at home

At this point, I had been officially working from home (WFH) for about 5 months. As an engineer, I was lucky to be able to WFH and our entire workforce had shifted to doing so. The adjustment to WFH had finally started to become routine, and the day-to-day was a bit more settled - basically, lots of video conferences and unresponsive CAD.

Introduction to Mechanical Switches

I think it’s fair to say that many users love the feeling of mechanical switches. They’re precise, tactile, audible, and just plain more satisfying to type with….